Table of Contents

What is a Metal Prefab Staircase?

A metal prefabricated staircase arrives at your site ready for installation, complete with all components such as stair treads, stringers, bolts, and brackets, all clearly labeled for easy assemble. This type of staircase is designed to save time and effort during setup. There are two main types: welded and mechanical, each with specific advantages. Regardless of the choice, ensuring that the staircase meets safety and building codes is important for compliance.

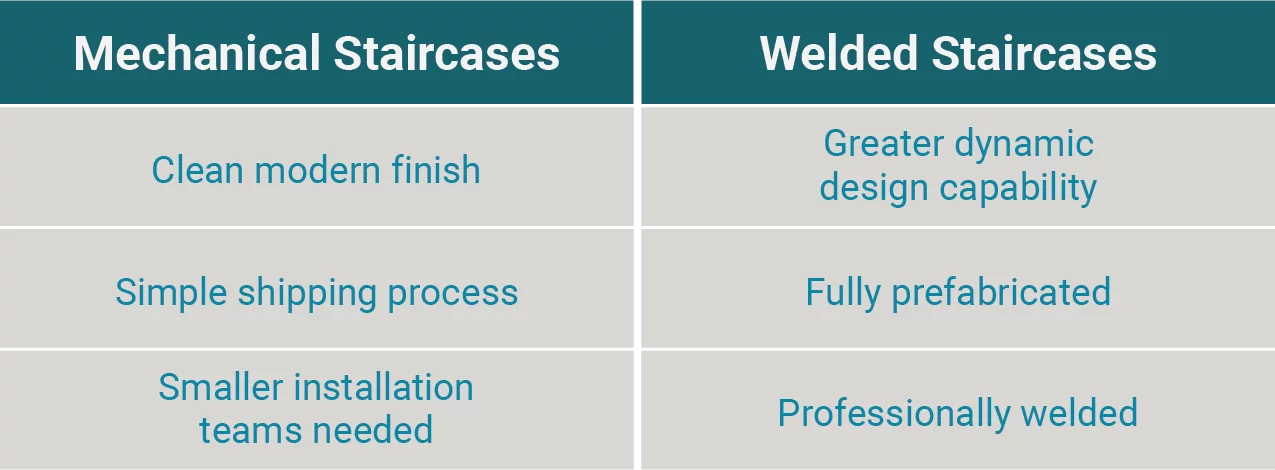

In general, there are two types of prefabricated stairs for metal stringers:

- Welded metal stairs

- Mechanical metal stairs

These staircases are manufactured in sections, which are then shipped pre-assembled to your location. The design helps save time during installation, as all parts, including treads, stringers, bolts, and brackets, are clearly labeled for easy assembly. Choosing between welded and mechanical staircases depends on specific needs, but both types are designed for quick setup and must comply with building codes for safety and durability.

Homeowners may opt for welded or mechanical metal staircases based on specific preferences, such as design or ease of installation. Regardless of the choice, ensuring compliance with building codes is crucial for safety and legal requirements.

Metal stair systems must meet either OSHA or IBC codes, depending on local building regulations. The relevant code depends on the space’s use: public or high-traffic areas typically have stricter requirements than private or low-traffic spaces. Be sure to check your local building codes for the specific guidelines.

What are the different types of prefab steel stair systems?

Steel Factory Welded Stairs

These stairs come with either open or closed risers. The standard width is 36″, with custom widths available. Treads are offered in bar grate or diamond plate options.

Pre-Engineered Landing

Lapeyre provides pre-engineered steel stairs with stringer and railing components. The treads come in metal pan, diamond, bar grate, or grip styles, while the stringers are available in plated, channel, or tube options.

Heavy Duty Treads

FSI Industries offers factory-welded stairs with a variety of finish options. An added benefit is their fireproof construction. The stair treads are available in diamond plate and bar grating, with widths of 36” and 40”. Special colors can also be requested.

Modern Design Stairs

Other manufacturers provide a modern design with hand-welded stairs, perfect for both indoor and outdoor projects.

What Is a Welded stair system?

These systems join stainless steel at key points in the staircase, including:

- Tread bracket to stringer or metal steps to stringer

- Header plates to stringer

- Footer plate to stringer

- Railing to metal tread or stringer

The entire stair unit usually arrives pre-assembled and ready for installation, making it fully prefabricated.

Are welded stairs more expensive than mechanical stairs?

The cost of a welded prefabricated staircase is similar to that of bolted prefabricated stairs. However, additional labor costs may apply for welding, especially if it needs to be done onsite. Bolted stairs might also incur extra costs for the components used in their connections.

Welded prefab stairs can range from $3,000 to $20,000, while mechanical stairs typically cost around $12,000.

What is a mechanical stair system?

Also called a bolted staircase, mechanical stair systems are made of metal and assembled using bolts and screws before being attached to steel tubing. One significant advantage is that the stair stringer can be shipped separately from the treads and other components, making on-site assembly easier and reducing the risk of shipping damage.

What are the similarities & differences between the two types of stairs?

A mechanical stair system is assembled using bolts and screws, eliminating the need for custom metal fabrication. Both systems use stainless steel.

The mechanical stair system includes many of the same components as a traditional welded staircase, such as tread brackets, header plates, and footer plates.

Both mechanical and welded systems meet the same code requirements. They must adhere to the 4″ sphere rule and support specific weight limits.

Bellointeriors Stair Design

Bellointeriors designs every aspect of the staircase with high-quality materials to ensure ease of installation and aesthetic appeal, with each piece connecting seamlessly.

What are the bolted connections?

The prefabricated staircase system consists of four main components: the stringer, header plate, footer plate, and tread brackets. The stringer serves as the backbone of the staircase, often exposed in floating designs. Header and footer plates securely attach the stringer to the floors with six bolts, enabling the system to support a weight load over five times the recommended limit. The tread brackets firmly hold each thread in place, connecting to the stringer and contributing to the staircase’s overall stability and strength.

Bolts, Connections, and Fabrication

We use high-quality grade 8 bolts for every connection, ensuring the prefabricated staircase is strong and secure. Made from tempered steel, these bolts are the strongest available in the United States, capable of withstanding extreme tension without breaking or fracturing.

Thread Locking

Thread locking enhances bolt connections by using a specialized adhesive applied to the threading during production, ensuring maximum strength at the connection point.

Flow drilling

In addition to using high-quality bolts, we connect components with a process called flow drilling. Unlike traditional welding, which can cause distortions and leave visible marks, flow-drilling creates a clean, threaded hole for bolts, eliminating unsightly “scars” where metals meet.

This process also simplifies shipping bolted stringers. By sending the stringer and brackets separately, without bulky pre-attached parts, customers can easily assemble them on-site.

Conclusion

Mechanical and welded prefabricated stairs each offer unique benefits, depending on your needs. Both options are durable, stylish, and ideal for modern homes. Welded stairs are robust and provide a seamless appearance, while mechanical stairs are easier to assemble on-site and more cost-effective. Both systems meet safety standards, ensuring long-term reliability.

Store Information

- 60, 29th Street, San Francisco, CA 94110, United States

- (+00) 123-456-789

- demo@example.com